|

|  |

July 2003 I got a call from journalist Andy Willsheer asking me to show my bike at the Essen Motorshow (D). As this is a famous show, I agreed. Besides: they offered me a huge payment of expenses :-) |

|

|

|

|

|

|

|

|

|

Soon after our conversation I received the official agreements. Actually, he sent two of them; one for the show in Essen, and one for CMT 2004 in Stuttgart, next January |

|

|

|

|

|

|

|

| |

Well, after 10,000 rainy kilometers in three years, the bike sure wasn't in showroom condition anymore. I'm not too bothered about that: people may see that this bike is no showbike but that it's actually used. But some radical cleaning had to be done, so I took the bike apart.

While I was at it, I decided to modify some minor and bigger aspects of the bike. I called these modifications 'Stage III', after 'Stage I' (CBX INOX original) and 'Stage II' (mirrors -> cameras, switches -> magneto switches, carbon fibre exhaust -> stainless steel exhaust). 'Stage III' turned out to be quite a drastic, time and money consuming operation. The four months I had until the Essen Motorshow were barely enough. | |

|

|

|

|

|

|

|

|

One of the more radical changes I made was replacing the fenders. The first and original fenders were made of carbon fibre, with a stainless steel strip in the middle. As steel and carbon fibre behave very different under pressure, the fenders turned out to be very vulnerable. And, moreover, I wanted them stainless to make the CBX INOX even more INOX.

Aim at the picture to view the new front fender. | |

|

|

|

|

|

|

|

|

Same story for the rear fender: aim at the picture to view the new rear fender. |

|

|

|

|

|

|

|

| |

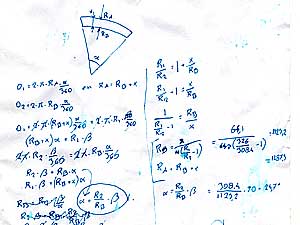

Like many things I've done before, 'The Making Of' turned out to be more complex than expected. Quite some calculations had to be made (thanks Jan!). |

|

|

|

|

|

|

|

| |

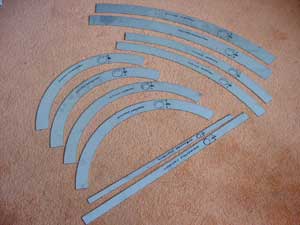

Then I had the 2mm thick strips lasered. Willy Naves took the risk to weld them, and succeeded. |

|

|

|

|

|

|

|

| |

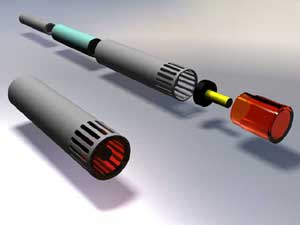

The former grips were made of rubber: no more! I designed stainless steel ones, with integrated indicators: like the fenders this made them less vulnerable and, moreover, the handlebar is now a complete stainless steel bar. |

|

|

|

|

|

|

|

|

|

The slots in the final versions of the grips were 5mm wide; 3mm wide slots meant breaking a lot of fraises. Aim at the picture to view the new grip. | |

|

|

|

|

|

|

|

|

Not as striking but important as well, is finishing the handlebar's old (and useless...) mirror holes.

Aim at the picture to view the result (clutch side).

|

|

|

|

|

|

|

|

|

|

Aim at the picture to view the result (brake side).

|

|

|

|

|

|

|

|

|

|

I replaced the (rusty...) steel headless M4 bolts with stainless ones.

Aim at the picture to view the result.

|

|

|

|

|

|

|

|

|

|

Just a few centimeters below the handlebar: the headlights. Black is beautiful, but not on my bike.

Aim at the picture to view the repainted headlights. | |

|

|

|

|

|

|

|

|

The forks' exteriors were a bit scratched. I disassembled and polished them.

Aim at the picture to view the result. | |

|

|

|

|

|

|

|

|

The forks again: this tube looks like it needs some attention, doesn't it? Being impossible to repair, I replaced both of them, as I did the oil seals and the anti-friction metals. Aim at the picture to view a new leg. | |

|

|

|

|

|

|

|

|

The front brake discs were 4.6mm thick. I replaced them as 4.5mm is the minimum thickness. Aim at the picture to view the new (well, almost new) discs. | |

|

|

|

|

|

|

|

|

I replaced the rusty steel bolts that held the front fender by stainless steel ones. Aim at the picture to view the result. | |

|

|

|

|

|

|

|

|

Again 'just' a detail, but details matter; this time the rusty front axle shaft. Aim at the picture to view the axle shaft. | |

|

|

|

|

|

|

|

|

Still at the front of the bike: I did some polishing on the exhaust pipes and replaced the bolts ... by stainless ones, of course. Aim at the picture to view the result. | |

|

|

|

|

|

|

|

|

Talking about the engine: due to heavy loss of compression it had to be taken apart. Klaus Sarembe replaced the pistons by 0.50mm oversized ones. He refaced the valve seats and replaced the valve guides (all 24 of them). Being at it, I had both cam chain guides replaced as well. Expensive, but necessary. |

|

|

|

|

|

|

|

|

|

The starter motor was the last black part of the engine. No more. Aim at the picture to view the repainted starter motor. | |

|

|

|

|

|

|

|

|

The front of the swing arm needed some welding. Aim at the picture to view the welded swingarm. | |

|

|

|

|

|

|

|

|

The inside of the swing arm needed attention as well. I replaced both bearing with sealed ones. The top of the swing arm was rounded to avoid the chain hitting it. Aim at the picture to view the changed swingarm. | |

|

|

|

|

|

|

|

|

I replaced the magnet that triggers the digital speedometer on the rear brake disc, by a more subtle one. And took some time for the finishing touch by spraying it.

Aim at the picture to view the improved rear brake disc.

|

|

|

|

|

|

|

|

|

|

I cleaned the chain and the sprocket. Aim at the picture to view the clean-up. | |

|

|

|

|

|

|

|

|

One detail I finally improved was hiding the rear brake hose. Of course it's in the swing arm now. Aim at the picture to 'view' the hidden brake hose. | |

|

|

|

|

|

|

|

|

Due to extreme temerature changes in the exhaust system the silencer tore. Willy Naves repaired it. Aim at the picture to view the welded silencer. | |

|

|

|

|

|

|

|

|

A leaking seal in the gas tank was repaired. Aim at the picture to view the leakless gas tank. | |

|

|

|

|

|

|

|

|

Four slotted bolts were replaced by more fancy ones. Aim at the picture to view the new bolts. | |

|

|

|

|

|

|

|

|

Again I replaced the bent and dented number plate. Have to do that once a year because people tend to overlook it at shows. Aim at the picture to view the fresh plate. | |

|

|

|

|

|

|

|

|

This annoying weld got some attention. Aim at the picture to view the improved weld. | |

|

|

|

|

|

|

|

|

The monoshock, held by two rusty bolts. Replaced them by som e nice stainless ones.

Aim at the picture to view a replaced bolt.

|

|

|

|

|

|

|

|

|

|

Finally, the result: more INOX than ever before!

More pictures soon to come.

Click the picture to enlarge it.

|

|