|

|

Of course the fuel tank had to be made of stainless steel and it had to be angular. Furthermore I didn't want a fuel cap on it. Since the alteration operation the (new) tankcover contains an LCD screen.

|

|

|

|

|

|

I made an unfolded projection of the tank in the 3D-program en printed it. |

|

|

|

|

|

|

|

|

|

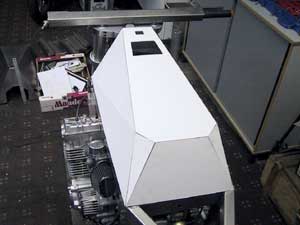

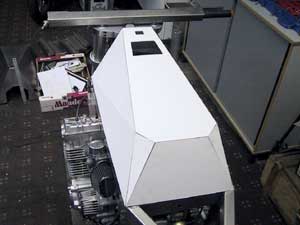

Copy it to cardboard, cut it out and stick the pieces together. |

|

|

|

|

|

|

|

|

|

The facets on the back are ergonomic concessions to the legs. Saves the leather overall too. |

|

|

|

|

|

|

|

|

|

Fitted like a glove! |

|

|

|

|

|

|

|

|

|

And this is how the first tank looked when it was made of stainless steel. |

|

|

|

|

|

|

|

|

|

I wanted the fuel cap, the electronics and the battery removed from sight. Therefore the 'fuel tank' is just a foldable cover. The real (aluminum) fuel tank has been placed underneath it. |

|

|

|

|

|

|

|

|

|

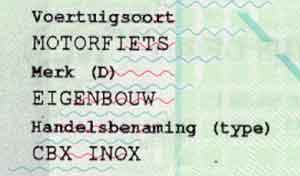

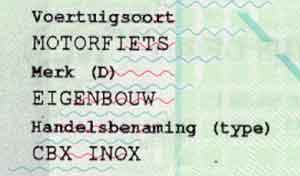

The registration certificate indicates that it's a self-built motorcycle. |

|

|

|

|

|

|

|

|

|

The sign 'SELFBUILT' should be placed somewhere on the frame. In my case it's on the frame, under the tank cover. |

|

|

|

|

|

|

|

Between September 2000 and June 2002 the CBX INOX was rebuilt drastically. So was the gas tank.

The idea of a 'mirrorless motorcycle' arose in the first sketch in 1997; and actually, old-fashioned mirrors don't belong on a futuristic bike. They interfere with the straight lines of the handlebar. I suspected that it wouldn't be easy to accomplish though, and I was right.

|

|

My investigation started September 2000. I contacted several security companies, electronics hobbyclubs and camcorder repair shops. I've sent emails and letters to Sony, Philips, Panasonic and other audio and video companies. Many mails and letters stayed unanswered, many wished me good luck (!), until someone gave me the address of the Orlaco company in Barneveld, NL. Orlaco is a young and innovative company that develops camera systems for commercial vehicles. |

|

|

|

|

|

|

|

|

|

January 2001 Jan and I visited Orlaco, and met Henrie and Gerrit van Beusekom. They arranged a guided tour through the company, and we discussed possible cameras and LCD screen. |

|

|

|

|

|

|

|

|

|

They were able to supply a 5,5" LCD screen at cost price, as well as all the technical help I would need.

At the bike we discussed the possibilities. |

|

|

|

|

|

|

|

|

|

Considering the fact that it was as new to them as it was to me, it took to June 2001 before the camera system was delivered. It took me another 10 months before everything was fully functional.

The screen required a new tank cover. First in cardboard ... | |

|

|

|

|

|

|

|

|

... and after that in stainless steel. |

|

|

|

|

|

|

|

|

|

The LCD screen was skillfully dismantled / demolished. |

|

|

|

|

|

|

|

|

|

The screen, the electronic parts and the speedometer had to be incorporated in the tank cover as efficiently as possible. After (of course) enduring some changes under the skilful leadership of Jan van Atteveld... |

|

|

|

|

|

|

|

|

|

The electronic parts are protected by a stainless steel plate. Behind the six holes there's a speaker installed. At the bottom left you see video and audio inputs to which external video sources can be connected (GPS, camcorder, ...). With the switch at the bottom right you can switch between the cameras and the external video source. |

|

|

|

|

|

|

|

|

|

Talking about cameras: both are nitrogen filled and heated so they won't get steamed up. Their view angle is 71 degrees. Normally you see the left camera view because the left mirror is mosltly used in traffic. With a magnet switch in the handlebar I can change from left to right camera view. |

|

|

|

|

|

|

|

|

|

And this is how it looks. The Sigma speedometer (above the LCD monitor) has the following characteristics: speed (up to 270 km/h), time, trip distance, total distance, average speed and maximum speed. | |