|

|

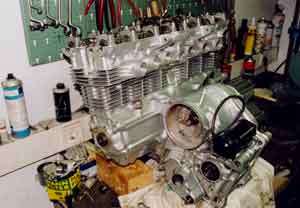

Everything taken apart, to the last bolt.

The pistons checked and weighed.

Honed the cylinder walls and put in new chains. A renewal of the pistons turned out to be unnecessary.

The engine is built up again.

The engine placed inside the frame.

And this is how the same alternator looks in my frame.

K&N-filters come with that: more power, beautiful intake-sound.

Picture: Lammert Steinfelder/KicXstart.

Picture: Lammert Steinfelder/KicXstart.

July until November 2003 I initiated 'Stage III': radical and less radical changes combined with necessary maintenance.

Talking about 'necessary maintenance': due to heavy loss of compression the engine had to be taken apart. Klaus Sarembe replaced the pistons by 0.50mm oversized ones. He refaced the valve seats and replaced the valve guides (all 24 of them). Being at it, I had both cam chain guides replaced as well. Expensive, but necessary.

The starter motor was the last black part of the engine. No more.

Aim at the picture to view the repainted starter motor.